Kahrs Engineered Flooring Installation

Wood flooring adds a timeless charm and a sense of sophistication to any interior. At FlooringFirst!, we celebrate the beauty and practicality of wooden floors, offering expert installation services for solid wood, parquet, and engineered flooring. Their natural appeal makes them a perfect fit for any style or décor, whether you're looking for a statement feature or a harmonious background.

For homeowners, wood flooring creates a spacious, cosy, and inviting ambience, while in professional spaces, it reflects elegance, professionalism, and durability. But wood flooring isn't just about aesthetics. Its natural strength, resilience, and ability to withstand wear and tear set it apart from other flooring types. Proper care and occasional refinishing ensure wood floors remain in pristine condition for decades — some even last up to a century!

Among the various options available, engineered wood flooring, such as Kahrs Engineered Flooring, stands out for its versatility, advanced design, and superior performance. Let’s explore its unique features and the reasons why it is considered a leading choice in the industry.

What Is Engineered Wood Flooring?

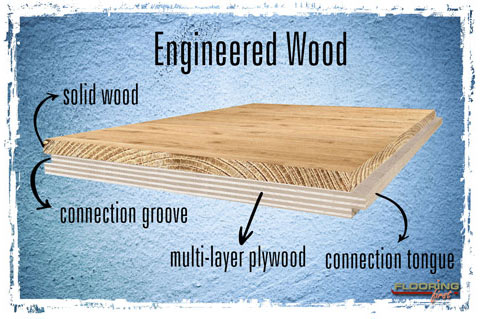

Engineered wood flooring is a versatile and advanced option that combines the beauty of natural wood with enhanced durability. Unlike laminate flooring, which only mimics the appearance of wood, engineered wood flooring is crafted from real wood layers and lumber by-products.

The construction involves layers glued together in a crisscross pattern, topped with a genuine hardwood lamella layer. This innovative structure provides superior resistance to moisture, humidity, and temperature fluctuations—common challenges for traditional solid wood floors.

This durability makes engineered wood flooring an excellent choice for spaces where solid wood might not perform well over time. Whether you're planning a floor for a bathroom, kitchen, basement, or conservatory, engineered wood can withstand conditions that would typically damage solid wood.

Why Choose Engineered Wood Flooring?

- Moisture Resistance: Its layered design minimises warping and expansion due to humidity.

- Versatile Installation: Compatible with various fitting methods like click systems, floating, glue-down, or nail-down, ensuring adaptability for any project.

- Ideal for Challenging Spaces: Perfect for rooms exposed to temperature changes or higher moisture levels.

- Enhanced Stability: The cross-layered structure ensures long-lasting durability.

Before installation, it’s vital to prepare the subfloor. Concrete subfloors, the most common base, must be checked for:

- Moisture levels: Excess moisture can affect even engineered floors.

- Evenness: Floors must meet tolerances to avoid instability.

- Cleanliness: Any debris or contaminants can interfere with the installation.

With its natural wood surface, exceptional strength, and flexibility in application, engineered wood flooring is a leading choice for both residential and commercial spaces.

Discover the Excellence of Kahrs Engineered Wood Flooring

Kahrs is a renowned name in the global wood flooring industry, celebrated for its premium quality, diverse product range, and competitive pricing.

Specialising in engineered wood flooring, Kahrs offers products with thicknesses of 14mm, 15mm, 18mm, and 20mm, featuring a durable top layer of 3.5mm hardwood options such as maple, beech, ash, walnut, or oak.

Kahrs floors come in an impressive variety of colours, grains, and textures, with stunning finishes that enhance their natural beauty. The brand’s engineered wood floors are particularly valued for their exceptional stability. Their patented construction makes them 75% more resistant to warping, buckling, and cracking compared to solid wood flooring—ensuring durability even in the face of humidity and temperature changes.

What sets Kahrs apart is its commitment to sustainability. Using raw lumber materials, they produce solvent-free and eco-friendly flooring solutions, combining beauty, durability, and environmental responsibility.

With Kahrs flooring, you get a product designed to maintain its elegance and integrity, even in challenging climates. Elevate your space with the unmatched quality and innovation of Kahrs engineered wood flooring.

Kahrs Engineered Flooring Installation Process

Kahrs is renowned for its innovative and reliable flooring installation systems, designed to ensure durability and ease of use. The brand offers two primary installation methods: the tongue & groove system and the click-lock system.

-

The Woodloc® Click-Lock System

Kahrs’ patented Woodloc® system is a glue-free, hassle-free installation method. This system features a special locking tongue that secures each board in place, creating a seamless, sturdy surface. It not only makes installation faster but also ensures superior strength and stability, providing a secure fit that lasts.

-

The Tongue & Groove Method

For those who prefer traditional installation methods, Kahrs offers the tongue & groove system, which involves fitting the tongue of one board into the groove of the next. This method typically uses wood adhesive, resulting in a highly durable flooring structure capable of withstanding the demands of time and traffic.

Why Choose FlooringFirst! for Your Kahrs Flooring Installation?

At FlooringFirst!, we specialise in installing Kahrs engineered wood flooring with precision and care. Our certified installers ensure that every plank is perfectly positioned, delivering a seamless and flawless finish that complements your space. Whether you choose the Woodloc® click-lock system for convenience or the tongue & groove method for its timeless durability, we provide expert guidance and execution.

If you haven’t chosen your Kahrs floor yet, browse our wide selection of Kahrs engineered wood flooring available in various colours, finishes and plank sizes. Get in touch today for a free quote and discover how Kahrs engineered flooring can transform your home or office with its unparalleled quality and elegance.

Frequently Asked Questions About Kahrs Engineered Flooring Installation

Is Kahrs engineered flooring a good choice for London homes?

Yes — Kahrs is known for its durability, stability, and stylish designs. It performs well in London’s climate and is suitable for both modern and traditional properties.

Can Kahrs engineered flooring be installed over underfloor heating?

Yes — Kahrs floors are fully compatible with underfloor heating systems, provided correct installation methods and temperature settings are followed.

What installation methods do you use for Kahrs floors?

We install Kahrs flooring using floating, glue-down, or nail-down methods, depending on the subfloor type and customer requirements. Kahrs’ Woodloc® system also allows fast and secure floating installation.

How long does it take to install Kahrs engineered flooring?

Most Kahrs installations take 1–3 days, depending on the size of the area, subfloor preparation, and fitting method chosen.

Do Kahrs floors need acclimatisation before installation?

Yes — Kahrs engineered flooring should acclimatise in your home for at least 48 hours before installation to ensure optimal stability.

Can Kahrs engineered flooring be sanded and refinished in the future?

Yes — most Kahrs floors have a quality wear layer that allows sanding and refinishing, extending the lifespan of your investment.