Boen Engineered Flooring Installation

Wooden flooring connects us to nature, bringing its natural warmth and charm into our homes and workspaces. By capturing the beauty and character of wood, we create spaces that feel timeless and inviting.

At FlooringFirst!, we are proud to partner with Boen, a world leader in engineered wood flooring. We offer supply and fitting services for their entire product range, ensuring exceptional quality and craftsmanship. Boen's innovative flooring options include:

- 1-strip and 3-strip engineered flooring with thicknesses from 10 to 23mm

- 20mm solid wood flooring, combining strength and elegance

- Engineered prefinished parquet blocks and tiles (10 to 12mm) for intricate designs

- Flooring compatible with sanding and restoration for long-term renewal

Benefits of Boen Flooring

1. Exceptional Durability and Finish

- Features six layers of wear-resistant, formaldehyde-free UV lacquer, ensuring a natural look with optimal grain-filling.

- Designed to withstand heavy foot traffic while maintaining its beauty over time.

2. Compatibility with Underfloor Heating

- Perfect for use with underfloor heating systems, enhancing comfort and energy efficiency.

- Exception: Boen beech and maple flooring are not recommended for underfloor heating due to their specific characteristics.

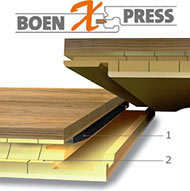

3. Innovative Installation System

- Equipped with the Boen Xpress System, a glueless installation technology that:

- Speeds up the installation process.

- Offers a clean and easy way to reverse or repair flooring when needed.

4. Diverse Range of Wood Species and Shades

- Available in a stunning variety of wood species, including:

- Oak, beech, ash, maple, merbau, walnut, iroko, and panga-panga.

- Offers a wide palette of shades and finishes to suit every style and preference.

Subfloor Requirements for Boen Engineered Wood Flooring

Ensuring the subfloor is in optimal condition is important before installing Boen engineered wood flooring. Adhering to these requirements guarantees a long-lasting and trouble-free installation.

1. Subfloor Essentials

- The subfloor must be dry, level, and self-supporting to accommodate Boen flooring properly.

- Approved subfloor materials include:

- 22 mm chipboard

- 19 mm plywood

- 21 mm floorboards

2. Moisture Content Standards

- The subfloor's moisture content should not exceed 12%.

- FlooringFirst operatives measure the subfloor's dampness and may delay installation if moisture levels exceed recommended limits to prevent future issues.

3. Structural and Sound Considerations

- Irregular sounds (like creaking) or faults in the subfloor should be addressed before the flooring is installed.

- A layer of flooring underlay must be added between the subfloor and engineered flooring to:

- Minimise friction and prevent noise.

- Absorb minor unevenness in the subfloor.

4. Special Requirements for Concrete Subfloors

- Concrete subfloors must be:

- Well-leveled, with a tolerance of ±3mm per 2 running metres.

- Free from lumps, debris, or other imperfections.

- For added protection against dampness:

- Use a DPM-enabled underlay or lay a 0.20mm thick plastic foil barrier.

5. Floor Coverings and Preparation

- Existing floor coverings like linoleum, vinyl, or plastic do not need removal, but placing a layer of plastic foil between them and the new flooring is recommended.

- Thin, firm carpets (e.g., needle felt) can serve as an effective underlay but are generally removed for hygiene reasons.

- All other types of carpet must be fully removed before installation.

Boen Engineered Flooring Installation Process

At FlooringFirst!, we follow a precise and proven installation process to ensure your Boen engineered wood flooring looks flawless and performs beautifully for years to come:

- 1. Subfloor Assessment & Preparation: We begin by ensuring the subfloor is completely dry, clean, and level. This step is crucial to guarantee a stable and long-lasting installation.

- 2. Moisture Protection: If needed, we install a high-quality damp-proof membrane (DPM) underlay to safeguard your floor against moisture and humidity issues.

- 3. Choosing the Right Installation Method: Based on the subfloor and location, we recommend either:

- Floating Installation: Boen’s innovative Xpress Click System allows for a fast, glue-free installation — perfect for quick renovations with minimal mess.

- Glue-Down Installation: Using premium adhesives, we firmly bond the floor to the subfloor, ideal for areas that need extra stability or noise reduction.

- 4. Precision Fitting: Our expert installers lay each plank with accuracy, using Boen’s recommended techniques to ensure perfect alignment and a seamless finish.

- 5. Expansion Gap Allowance: We leave proper gaps around the perimeter of the room to accommodate the natural expansion and contraction of the wood.

- 6. Finishing Touches: Trims, thresholds, and skirting boards are installed or refitted to complete the polished look of your new floor.

With FlooringFirst!, you're guaranteed a Boen flooring installation that's smooth, efficient, and built to last.

To explore all our professional fitting options, visit our floor installation services page and discover how we can help with your next flooring project. Haven’t chosen your floor yet? Browse our wide selection of Boen engineered wood flooring available for online purchase or in-store consultation.

Frequently Asked Questions About Boen Engineered Flooring Installation

Is Boen engineered flooring suitable for London homes?

Yes — Boen engineered flooring is designed for stability in varying climates and works perfectly in London properties, including flats, houses, and commercial spaces.

Can Boen engineered flooring be installed over underfloor heating?

Yes — Boen floors are compatible with most underfloor heating systems, provided the correct installation method and temperature guidelines are followed.

What installation methods do you use for Boen floors?

Depending on the subfloor and customer preference, we can install Boen engineered flooring using floating, glue-down, or nail-down methods for long-lasting results.

How long does it take to install Boen engineered flooring?

Most installations take 1–3 days, depending on the size of the area, subfloor preparation, and the chosen fitting method.

Do Boen floors need acclimatisation before installation?

Yes — like all engineered wood, Boen flooring should be left to acclimatise in your home for at least 48 hours before fitting to ensure stability.

Can I sand and refinish Boen engineered floors in the future?

Yes — Boen engineered floors come with a durable wear layer that allows sanding and refinishing, giving you the option to refresh their look years after installation.