Back to Wood Floor Fitting

Moisture and Humidity: Key Considerations for Wood Flooring

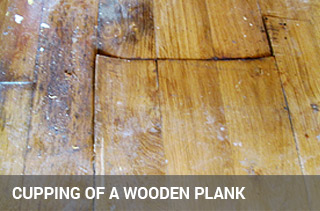

The majority of issues affecting wooden floors stem from moisture. Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture from the surrounding environment. As seasons change and atmospheric conditions fluctuate, wooden floors undergo regular shrinkage and expansion. This constant movement can lead to various problems, including buckling, curling, cupping, gapping, and crowning.

Moreover, excessive moisture creates an ideal environment for the growth of mould and mildew, which can further damage your flooring and compromise indoor air quality. These moisture-related issues can be quite costly to repair and can significantly shorten the lifespan of your floor.

To ensure the durability and aesthetic appeal of your wooden floor, it is crucial to control both moisture and humidity levels. This begs the question: how can you effectively manage moisture and humidity in your home?

Relative Humidity

Relative humidity (RH) refers to the amount of moisture present in the air relative to the maximum amount of moisture that the air can hold at a specific temperature. As the temperature increases, the capacity of air to hold water vapour also increases, leading to a higher evaporation rate of water from surfaces. Consequently, when the air gets warmer, water vapour evaporates into the atmosphere, raising the relative humidity levels.

Relative humidity is typically expressed as a percentage. For example, an RH of 50% means that the air is holding half of the total moisture it can contain at that temperature. Understanding relative humidity is crucial because it affects both the comfort of occupants and the condition of materials within a space, particularly wood flooring.

Maintaining an optimal relative humidity level (ideally between 30% and 50%) is essential for preventing issues like wood expansion and contraction, which can lead to warping or cracking of hardwood floors. Monitoring and controlling indoor humidity can be achieved through the use of dehumidifiers, humidifiers, and proper ventilation.

Wood Moisture Content

Moisture content (MC) refers to the amount of water or water vapour present in a given substance. In the flooring industry, it specifically measures the weight of water contained in the wood compared to a sample of the same species that has been dried at a specific temperature for a defined period. This measurement is important as it affects the wood's stability, durability, and overall performance.

Every living tree naturally contains moisture, as its cellular structure includes pores and cells that facilitate the transportation of nutrients throughout the trunk. After a tree is cut down, the remaining moisture must evaporate to make the wood suitable for use. However, this drying process can be time-consuming. To expedite this, lumber mills employ kiln drying, a method that removes most of the moisture from the wood while preserving its cellular structure. This ensures that the wood can still transport vapour, maintaining its integrity and functionality.

In the flooring market, most hardwood products typically have a moisture content ranging between 6% and 9%. This moisture range is essential for the stability of the flooring once installed - wood that is too wet or too dry can lead to various problems such as warping, cracking, and gaps between floorboards.

When selecting hardwood flooring, it’s important to check the moisture content to ensure that it aligns with the climate conditions of your installation area. Additionally, acclimating the wood to the room's temperature and humidity before installation can help mitigate issues related to moisture and ensure a long-lasting, beautiful floor.

Equilibrium Moisture

Equilibrium moisture content (EMC) refers to the state where the moisture content of wood stabilises and balances with the humidity levels of its surrounding environment. Water vapour in the air continuously seeks equilibrium; therefore, the interaction between the air's relative humidity (RH) and the wood's moisture content (MC) plays a critical role in this process.

When the relative humidity of the air is higher than the moisture content of the wood, the wood will absorb some of the excess humidity, leading to an increase in its moisture content. Conversely, if the air is drier (lower RH), the wood will release some of its moisture into the air, resulting in a decrease in its moisture content.

Once the wood reaches a point where it neither gains nor loses water vapour, it has achieved its equilibrium moisture content. This state is vital for maintaining the stability of wood flooring. If the wood’s MC is consistently above or below the EMC, it can lead to problems such as:

- Swelling and Cupping: Excess moisture can cause the wood to swell, leading to cupping or warping of the floorboards.

- Cracking and Splitting: Low moisture levels can cause the wood to shrink, resulting in cracks and splits.

- Gapping: Fluctuations in moisture can create gaps between floorboards, compromising the floor's aesthetic and structural integrity.

Understanding EMC is essential for homeowners and professionals alike when installing and maintaining wood floors. Proper acclimation of the wood to the installation environment, along with consistent monitoring of humidity levels, can help ensure that the flooring remains stable and visually appealing for years to come.

Controlling Moisture before Floor Installation

Controlling moisture levels is very important for successful wood floor installation. If there is a disparity between the humidity in the air and the moisture content in the floorboards, the wood will either gain or lose moisture until equilibrium is achieved. This process can lead to significant dimensional changes in the floorboards, affecting their width and thickness. To minimize these issues, it is essential to allow the floorboards to acclimatise in the installation environment for at least two weeks before installation. Failing to follow this rule may result in warping and other unpleasant deformities, especially with exotic timber sourced from regions with vastly different climates.

Steps to Control Moisture Before Installation

-

Acclimatisation: Allow wood floorboards to acclimatise for a minimum of two weeks in the room where they will be installed. This process helps the wood adjust to the temperature and humidity of its new environment, reducing the risk of warping or buckling after installation.

-

Check Subfloor Moisture Levels: It's vital to ensure that the subfloor has appropriate moisture levels before fitting your new floor. Using a moisture meter is the most effective way to gauge the moisture content. If the subfloor is made of timber, take around 30 readings throughout the area to ensure consistent results. Ideally, the moisture content should be around 2-3%. For a timber subfloor, the perfect moisture level is 12%; lower moisture levels are preferable.

-

Assessing Concrete Subfloors: Concrete subfloors can present more challenges, as they are prone to moisture problems. The ideal relative humidity for a concrete subfloor is between 35-40%; however, achieving this is rare. In such cases, it is essential to use an underlay with a moisture barrier or, even better, install a damp-proof membrane (DPM). This additional layer will help protect the wood flooring from potential moisture infiltration from the concrete slab, safeguarding its longevity and performance.

By taking these proactive steps to manage moisture levels before installation, you can help ensure the stability and durability of your wood flooring, leading to a successful and long-lasting installation.