Back to Wood Floor Fitting

Does Engineered Wood Flooring Work with Underfloor Heating?

Engineered wood flooring is renowned for its numerous benefits, one of which is its compatibility with underfloor heating systems. This cost-efficient heating solution allows homeowners to enjoy a cosy environment while keeping heating bills lower during the winter months. Engineered wood flooring can be used with all types of underfloor heating, but there are several important factors to consider for a successful installation that ensures both the flooring and heating system work effectively and last for decades.

Initial Considerations for Underfloor Heating Installation

Before installing an underfloor heating system beneath your engineered wood floor, obtain written confirmation from your supplier that the entire system is compatible with controlled temperatures. This serves as a guarantee that the heating system will operate efficiently, preventing potential damage to the flooring from excessive heat. In addition to room statistics, ensure you have flow control valves and floor temperature probes. It's also highly recommended to utilise a few floor temperature data loggers to provide proof that the floor has not overheated, which can be crucial for any warranty claims.

Checking Key Factors for Successful Installation

After addressing the initial requirements, it’s important to consider additional aspects to ensure the effective performance of both the heating system and the engineered wood flooring:

-

Moisture Content:

- Check the moisture content of the concrete subfloor to ensure it does not exceed the recommended limit.

- Verify the moisture content of the engineered wood flooring itself. If either exceeds acceptable levels, consult with your local wood floor installation service for professional advice.

- The relative humidity in the room should not exceed 65%.

-

Subfloor Conditions:

- The maximum deviation in flatness should be less than 3 mm per linear meter.

- Ensure your subfloor is a closed and self-supporting surface, as other types of subfloors may not be compatible with underfloor heating.

- Before installation, thoroughly clean the subfloor to ensure it is completely dust-free. If there are layers of plywood or chipboard, ensure they are in good condition, replacing them if necessary.

Professional Installation of Underfloor Heating

One crucial aspect to keep in mind is that underfloor heating systems should always be installed by experienced professionals. Attempting to install underfloor heating as a DIY project can lead to costly failures and may even pose safety risks. Ensuring that all installation work is carried out by skilled experts guarantees optimal results and maximises cost efficiency.

Key Considerations for Successful Installation

To successfully install an underfloor heating system, follow these essential guidelines:

-

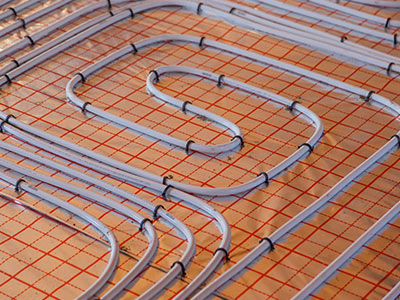

Proper Placement of Hot Water Pipes:

- Ensure that all hot water pipes are adequately positioned below the top surface of the screed. This placement promotes even heat distribution and helps prevent the formation of hot spots.

-

Sufficient Insulation:

- It’s important to have adequate insulation beneath the underfloor heating system. This insulation not only enhances energy efficiency but also helps to protect the flooring above.

-

Use of Underlay:

- If recommended by your installation professionals, consider installing an underlay. Failing to do so may allow moisture to be drawn up by the screed, compromising the integrity of the cement screed and significantly reducing the efficiency of the underfloor heating system.

By prioritising professional installation and adhering to these key considerations, you can ensure that your underfloor heating operates effectively and efficiently for years to come.

Commissioning by the Underfloor Heating Installer

Proper commissioning of the underfloor heating (UFH) system is essential for optimal performance and longevity. The installer should follow a specific temperature adjustment process to ensure the system operates effectively:

-

Initial Temperature Setting:

- On the first day, the installer will set the temperature to 20°C.

-

Gradual Temperature Increase:

- Over the next eight days, the temperature should be increased by 5°C each day, reaching a maximum of 45°C.

-

Maintenance at Maximum Temperature:

- Once the maximum temperature is achieved, it should be maintained at 45°C for an additional eight days.

-

Gradual Temperature Decrease:

- After this period, the temperature should be decreased by 5°C each day over the following eight days.

Total commissioning time should take approximately 21 days.

Important Considerations During Installation

-

Turn Off the UFH System: Before installing the flooring, ensure the underfloor heating system is completely turned off. This precaution should be maintained throughout the entire installation process.

-

Heating Post-Installation: After the floorboards are fitted, turn the heating system back on and allow it to run for at least two days.

-

Finishing and Oiling the Floor: When applying finishes or oils to the floor, follow the manufacturer's instructions carefully. In some cases, you may need to wait for at least two weeks before applying any finishing products.

By adhering to these commissioning guidelines, you can help ensure your underfloor heating system functions effectively and supports the longevity of your engineered wood flooring.

Avoid Extreme Temperatures

After the installation of both the underfloor heating system and the engineered wood flooring, it's important to protect your floor from temperature fluctuations and humidity extremes. Here are some key considerations:

-

Minimise Temperature Fluctuations:

- Ensure the floor is not subjected to significant temperature changes. Avoid exposing it to high humidity and extreme temperatures during this initial period.

-

Maintain Low Heating Levels:

- Ideally, the underfloor heating system should never be completely turned off. Instead, keep it running at a very low temperature to maintain a stable environment.

-

Control Relative Humidity:

- Maintain a relative air humidity level between 40% and 65%. This is vital for preventing the wooden floorboards from becoming too dry and at risk of damage.

-

Use Air Humidifiers:

- Consider using air humidifiers to help achieve and maintain the desired humidity levels in your home.

By taking these precautions, you can help ensure the longevity and performance of your engineered wood flooring while maximising the efficiency of your underfloor heating system.