Back to Flooring Products

Understanding Wear Layers in Engineered Hardwood Flooring

Engineered hardwood flooring has become a top choice for UK homeowners, architects, interior designers, and professional tradespeople thanks to its elegant appearance and practical performance. One critical feature that directly influences its durability and lifespan is the wear layer.

Engineered hardwood flooring has become a top choice for UK homeowners, architects, interior designers, and professional tradespeople thanks to its elegant appearance and practical performance. One critical feature that directly influences its durability and lifespan is the wear layer.

But what exactly is the wear layer, why does it matter, and how do you choose the right thickness for your space? In this guide, we’ll go deeper into engineered wood’s wear layer, providing all the answers and advice you need to make a confident flooring investment.

What Is the Wear Layer?

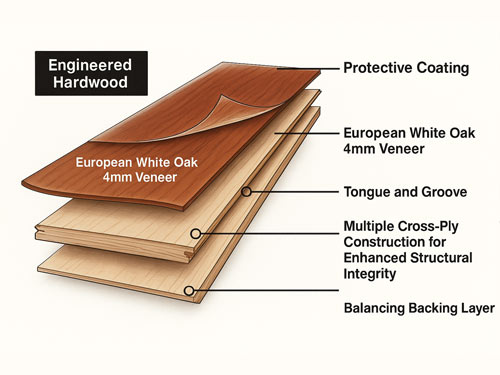

The wear layer of an engineered hardwood plank is the top layer of real hardwood veneer that sits above the plywood base. It’s what you see and feel when walking across the surface—and more importantly, it's what takes the brunt of everyday use.

While the inner core of engineered wood comprises layers of plywood or HDF (high-density fibreboard) arranged in a criss-cross grain pattern for stability, the wear layer is made from a solid slice of hardwood such as oak, walnut, or maple.

Why the Wear Layer Is So Important

- Durability: A thicker wear layer allows the flooring to be sanded and refinished multiple times over its lifespan. This helps remove scuffs, dents, and surface damage, keeping the floor looking like new.

- Lifespan: With proper care and maintenance, thicker wear layers can extend the lifespan of engineered hardwood floors significantly—up to 30 years or more.

- Cost Effectiveness: Thicker wear layers can translate into better long-term value. Yes, they may cost more upfront, but being able to refinish your floor repeatedly can save money on replacement costs down the line.

- Versatility: Thinner wear layers may be suitable for low-traffic areas or renovations where build height is limited, providing flexibility.

Common Wear Layer Thicknesses Explained

Engineered hardwood floors typically come with one of the following wear layer thicknesses. Each is suited to different usage scenarios:

- 0.6mm – 1.2mm: Ideal for budget projects or where flooring won’t be exposed to heavy wear. No sanding is possible.

- 2mm – 3mm: Suitable for most residential applications. It can usually be refinished once if carefully done.

- 4mm – 6mm: Best suited for high-traffic areas or long-term investments. Can be sanded and refinished multiple times, similar to solid hardwood.

What to Consider Before Choosing a Thickness

Selecting the right wear layer thickness is not about choosing the thickest option—it’s about choosing the most appropriate for your needs, budget, and lifestyle. Consider these factors:

- Foot traffic: Homes with children, pets, or open-plan layouts tend to benefit from thicker wear layers.

- Refinishing potential: Want to keep your floor looking good for decades? Thicker layers provide that flexibility.

- Budget constraints: If you're flipping a house or doing a short-term let project, thinner layers might be more cost-effective.

- Structural height: In renovations or upper floors where every millimetre counts, thinner planks might suit better.

Wear Layer vs Total Thickness: What’s the Difference?

Many consumers confuse wear layer thickness with total plank thickness, which can lead to misconceptions about the durability and longevity of engineered hardwood flooring. While a product may boast a 15mm total thickness, this measurement includes the base, core, and wear layer, not just the portion of the floor that directly impacts performance. The total thickness can affect the floor's stability and comfort underfoot, but it’s the wear layer that plays a key role in the floor’s long-term maintenance and appearance. The wear layer is the topmost layer of the floor that is exposed to daily wear, scratches, and scuffs. A thicker wear layer allows for multiple sandings and refinishing sessions, extending the life of the floor.

Always enquire about the wear layer thickness specifically, as this will determine your ability to maintain and refresh the floor over time. A thinner wear layer, such as those under 2mm, may limit refinishing options, while a thicker wear layer (3mm or more) offers the flexibility to sand down imperfections or change the finish when necessary. Keep in mind that the wear layer is also important for ensuring that the engineered hardwood maintains its aesthetic appeal, as it directly affects how well the floor holds up against stains, scratches, and the general wear and tear of everyday use. So, when shopping for engineered hardwood, don't just focus on the total thickness—understanding the wear layer's depth is essential for making an informed choice that aligns with your maintenance and durability expectations.

Real-World Examples from the UK Market

To help clarify how wear layer thickness plays a role in real-life applications, let’s explore a few examples of how different UK homeowners and professionals might select the right wear layer for their needs:

- Young Professionals in a London Flat:

For a stylish yet affordable option, young professionals living in a flat with lower foot traffic might opt for a 2mm wear layer. This thickness strikes a good balance between cost and durability, providing a sleek look for areas like living rooms or bedrooms where wear is light. It offers enough protection for those who aren’t hosting large gatherings but still want a visually appealing floor.

- Architect Designing a Family Home in Surrey:

A 4mm wear layer is often ideal for a family home, where foot traffic and general wear can be more significant. This thickness ensures the flooring is durable enough to withstand the wear and tear of active kids, pets, and daily family life. It also offers long-term value, as it can be refinished over time without the risk of prematurely wearing through the top layer. The extra thickness also provides added aesthetic depth, making it a great choice for spaces that need both durability and beauty.

- Tradesmen Renovating a Holiday Cottage in Cornwall:

In a holiday rental or vacation home, a 3mm wear layer is a practical choice. It offers sufficient durability to withstand the demands of occasional but varied traffic, such as sandy feet and heavy luggage. The 3mm wear layer also strikes a great balance between cost and resilience, and it can handle the frequent turnover of guests who might not be as gentle on the floors as homeowners. This thickness ensures that the floor can still be maintained and refinished if needed, without compromising the overall aesthetics.

These examples illustrate how selecting the right wear layer can depend on both the functionality and style desired for each specific space. Whether it's for an urban flat, a bustling family home, or a high-traffic holiday property, understanding the wear layer's role ensures the right decision is made to match the unique needs of each project.

Installation Tips to Preserve Your Wear Layer

To ensure the longevity and durability of your engineered hardwood flooring and its wear layer, consider these helpful installation and maintenance tips:

- Use Appropriate Underlayment:

An underlayment not only provides additional soundproofing but also helps protect the underside of the flooring from moisture, dirt, and potential damage. This is especially important for preserving the integrity of the wear layer over time. Select a high-quality underlayment that complements your flooring type and enhances performance.

- Acclimatise the Wood:

Before installation, allow the planks to acclimate to the room’s temperature and humidity for at least 48 hours. This prevents expansion or contraction post-installation, which could damage the wear layer. Ensuring the wood has adjusted to the room conditions promotes stability and avoids potential issues such as buckling or gaps over time.

- Avoid Wet Mopping:

While engineered hardwood is more water-resistant than solid hardwood, excess moisture can still damage the wear layer. Avoid using a wet mop or soaking the floor with water, as this can cause the wood to warp and affect its finish. Instead, use a damp cloth or a floor-specific cleaning solution designed for wood surfaces to clean the floor without compromising its wear layer.

- Use Furniture Pads:

Place felt pads or protective coasters under furniture legs to prevent unnecessary scuffs, scratches, or marks that can wear down the finish. This small step can significantly extend the life of your flooring by preventing friction damage from moving chairs, tables, or other heavy furniture.

By following these installation and care tips, you can ensure that the wear layer of your engineered hardwood flooring remains intact, maintaining its beauty and functionality for years to come.

Final Thoughts: Choosing the Right Wear Layer

Whether you're a DIY enthusiast planning your first floor install, a professional interior designer specifying for clients, or a builder managing multiple renovations, the wear layer of engineered hardwood provides critical functional and aesthetic value. Be sure to weigh your current needs against long-term goals and usage habits.

In most cases, a 3mm or 4mm wear layer offers the best blend of performance, refinishing potential, and cost-efficiency, making it a wise choice for UK homes and commercial spaces alike.

Need help assessing which engineered wood product is best for your project? Don’t hesitate to contact us for expert guidance.